技术文章

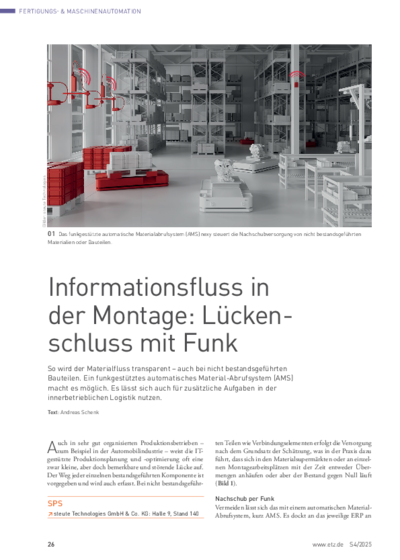

Information flow on the shop floor: closing the gap with wireless technology

Material flow made transparent – also for non-inventory-managed items. A wireless-based automated material requisition system (AMS) provides the solution and can also be used for other intralogistics tasks.

Source: etz (S4/2025)

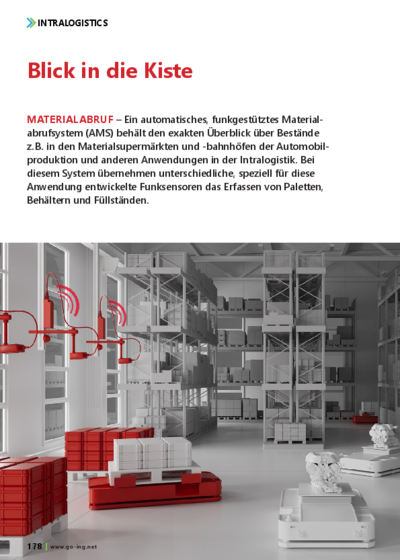

Bin surveillance

MATERIALS REQUISITION – An automated wireless material requisition system (AMS) maintains an accurate overview of all stock in e.g. materials supermarkets and stations used in automotive manufacturing, as well as other intralogistics applications. Within this system, a range of wireless sensors developed specifically for such use cases detects pallets, load carriers and fill levels.

Source: GO>>ing (eMagazine Nr. 4/2025)

Open or proprietary? Wireless networks for industry

When selecting wireless networks for their industrial production, many factory planners favour open rather than proprietary networks. However: this apparent contradiction begins to blur, the closer one looks. A comparison of the two systems shows why.

Source: NET (6-7/2020)

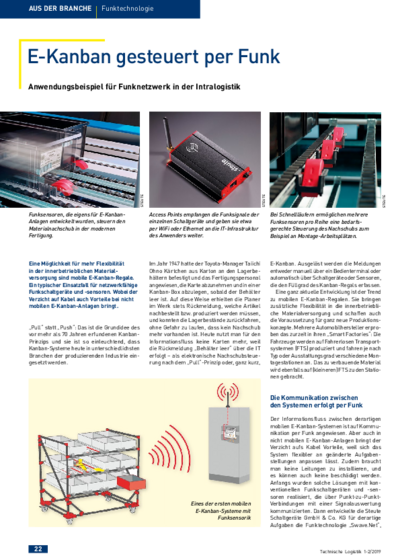

Remote-controlled eKanban - Application example of a wireless network for intralogistics

One way of achieving more flexibility when replenishing materials in the factory is mobile eKanban racks: a typical application for network-compatible wireless switching devices and sensors. Eliminating cables is also beneficial for non-mobile eKanban systems, however.

Source: Technische Logistik (1-2/2019)

Cable-free Kanban

In conjunction with flexible product manufacturing, processing, storage and consignment, information flow needs to be equally flexible. This in turn has an impact on the sensors and switches used at shop floor level. Wireless networks have become increasingly popular here, for example for eKanban systems, due to their many advantages. steute has developed its very own wireless network precisely for such applications, and it managed to include pre-designed modules in time for the LogiMAT 2019.

Source: etz (1-2/2019)

Remote-control wake-up for AGV

Mobile conveyor technology requires new communication structures between production plants and superordinate IT systems. Car manufacturers have opted here for wireless technology.

Source: konstruktionspraxis (01/2019)